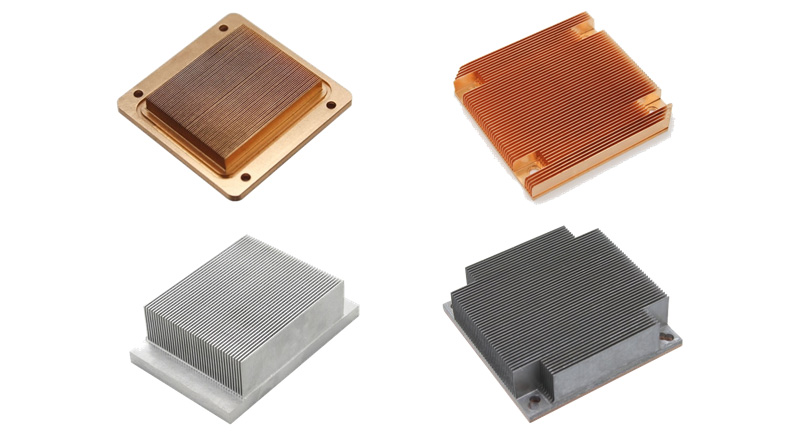

Shovel -tooth radiator(Copper/aluminum)

Shovel-tooth is also known as SKIVING technology. Simply put a piece of aluminum or copper is cut into fins with a standard pitch and a certain thickness and height through a special shovel machine as needed. Due to the use of high-precision cutting technology and integrated forming, compared with other processing techniques, the same volume of raw materials can cut a larger heat dissipation area, the heat transfer performance is more stable, and the heat dissipation efficiency can be increased by 10-30% compared with the insert heat sink Thereby greatly improving the heat dissipation efficiency and extending the service life of heating components.

Since the sprocket and the substrate are of the same material, there is no contact thermal resistance between the heat dissipation sprocket and the substrate, and the ratio of the height of the sprocket to the spacing of the sprocket is very large (copper can reach 25, and aluminum can reach 60). The heat dissipation fins are thin and dense, which greatly increases the heat dissipation area. Even if the air volume is reduced, the radiator can still achieve a good heat dissipation effect, thereby greatly reducing the noise generated by the fan, and can dissipate a large amount of heat in a limited space to meet the heat dissipation requirements.

Advantages of high-density shovel-tooth radiator

(1) The shovel-tooth radiator has a higher fin density, increases the heat dissipation area, and improves the heat dissipation performance;

(2) The height of the blades of the shovel-tooth radiator can reach 120mm, which fully meets the production requirements of most radiators;

(3) The teeth of the spade radiator can be made thinner, generally 1.5mm or even 1.0mm, which can make the radiator lighter;

(4) The shovel-tooth radiator is shoveled on the prototype material, so the heat dissipation efficiency is not damaged, reaching 100% of the heat dissipation efficiency of the prototype material, and there will be no risk of loosening and falling, improving the reliability of machine operation;

(5) The shovel-tooth radiator has high compatibility, and the possibility of later processing is also great. It can also cooperate with the buried heat pipe process to improve the heat dissipation performance.

High precision CNC skiving machine

Technical parameter:

Manufacturing process: shovel-tooth (SKIVING technology);

Product material: AL1060, AL6063-T5, CU1100;

Assembly strength: SUS threaded sleeve, extrusion tap tapping.

Process parameters of AL1060

|

Substrate thickness

|

Single tooth width L

|

Tooth height H

|

Tooth thickness

|

Tooth pitch

|

Product length

|

|

1-30mm

|

<600mm

|

<120mm

|

0.25-2.0mm

|

0.2-6.5mm

|

3000mm

|

Process parameters of CU1100

|

Substrate thickness

|

Single tooth width L

|

Tooth height H

|

Tooth thickness

|

Tooth pitch

|

Product length

|

|

1~30mm

|

﹤300mm

|

﹤120mm

|

0.25~2.0mm

|

0.2~6.5mm

|

3000mm

|

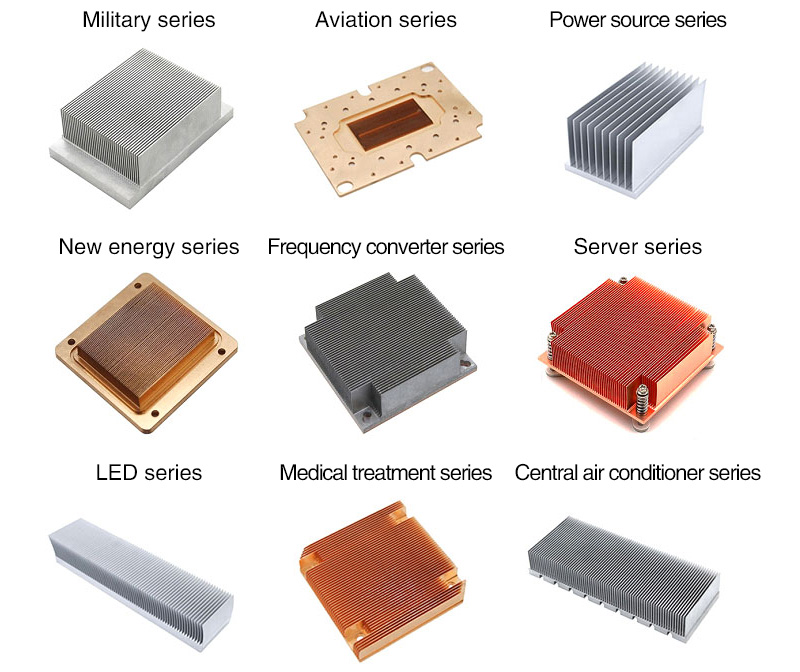

Application field

High-density shovel-tooth radiators can be used in servers, communications, industrial control, LED, medical, photovoltaic, wind power, inverters, rail transportation, new energy vehicles, radio and television transmitters, military industry, test equipment and other fields.

Custom classification of shovel-tooth radiator:

Water cooling shovel-tooth

Copper and aluminum composite shovel-tooth

Shovel-tooth radiator + heat pipe