Introduction of radiating coating product

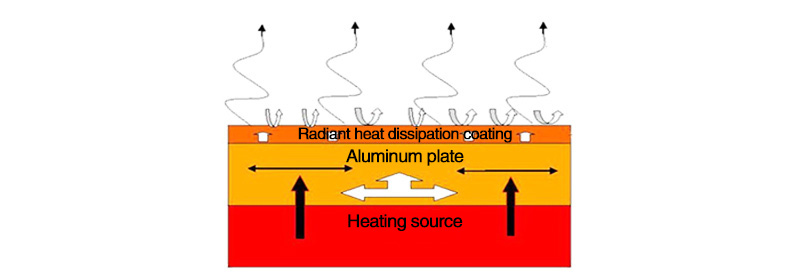

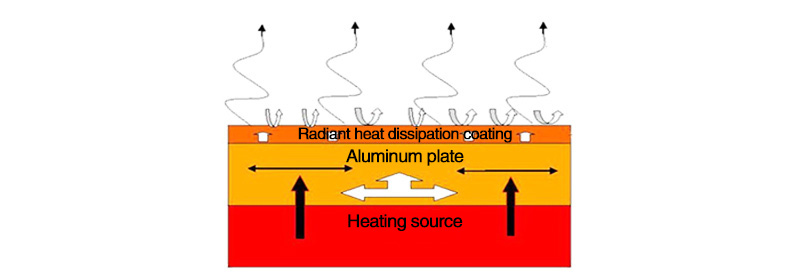

High-emissivity infrared ceramic radiation heat dissipation coating is a two-component high-emissivity infrared radiation ceramic coating. It uses the high thermal conductivity and high emissivity of infrared ceramics to transfer the surface heat of high-temperature devices into the coating and use infrared The method radiates to the outside world, accelerates the heat exchange between the device and the outside world, reduces the surface and internal temperature of the device, so as to achieve the effect of improving the stability and service life of the device.

Principle of product radiation

Principle of product radiation

Main physical parameters

|

Color/color number:

|

Black/RAL 9005 (color can be customized)

|

|

Paint surface:

|

Flat light

|

|

Table stem:

|

1 hour (25℃)

|

|

Thoroughly dry:

|

4 hours (25℃)

|

|

Fully cured:

|

7 days (25℃)

|

|

Temperature resistance:

|

600℃

|

|

Infrared radiance:

|

0.86-0.92 (2-25μm)

|

|

Thermal conductivity:

|

2W/(m˙K)

|

Main performance

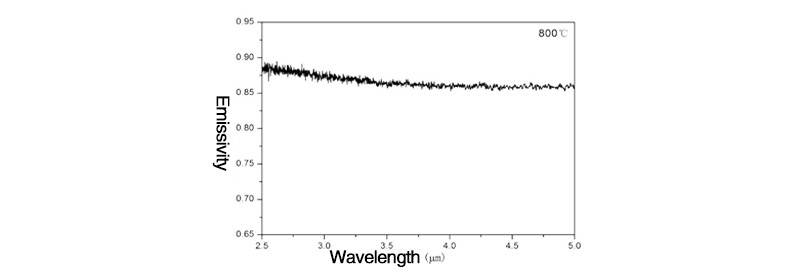

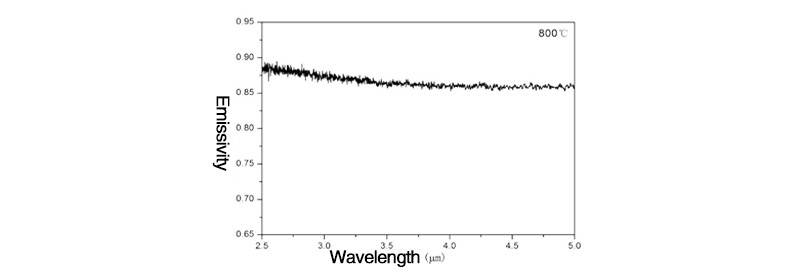

(1) High infrared emissivity: The emissivity of the coating in the infrared (2-25 μm) band is 0.86-0.92, with small temperature dependence;

(2) Excellent radiation heat dissipation performance;

(3) Excellent aging resistance;

(4) Excellent thermal conductivity;

(5) Excellent mechanical properties and salt spray resistance;

(6) Excellent construction performance.

Infrared radiation rate of coating at 800℃ (3~5 microns)

Infrared radiation rate of coating at 800℃ (3~5 microns)

Ultra-high temperature radiation cooling

Blank AI substrate plate(Burn through time)=30s Coated Infrared substrate plate(Burn through time)=210s

Blank AI substrate plate(Burn through time)=30s Coated Infrared substrate plate(Burn through time)=210s

The burn-through time is extended by 7 times! → The radiation cooling effect is remarkable!

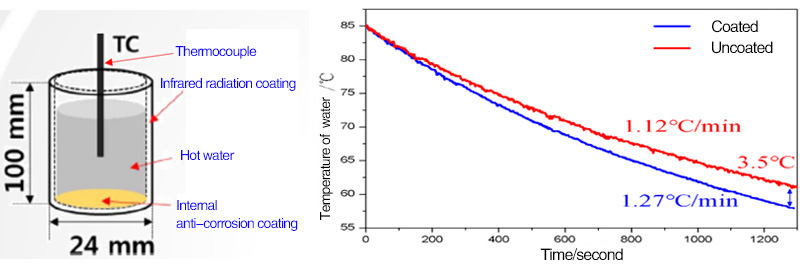

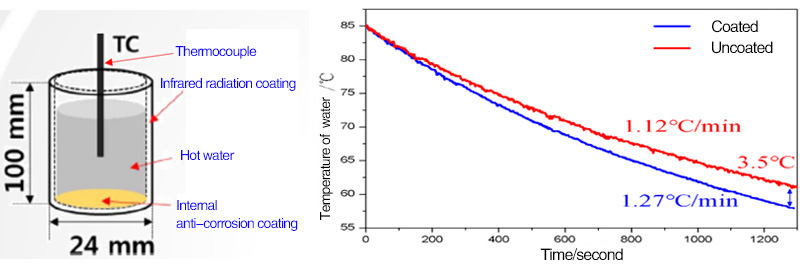

Lower temperature radiation cooling

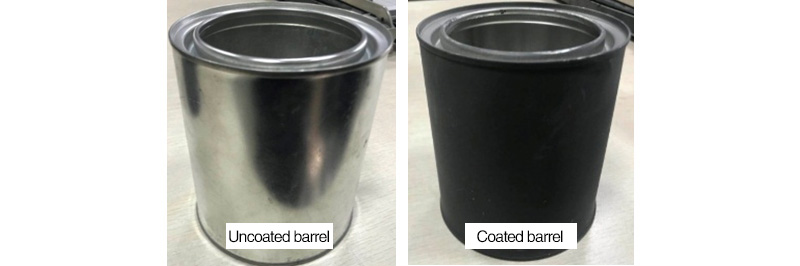

Lower temperature radiation cooling test device cooling curve In 600g 85℃ water 22min

Lower temperature radiation cooling test device cooling curve In 600g 85℃ water 22min

Increase in cooling rate: 13%

Cooling temperature difference: 3.5℃